The Definitive Guide to Water Filtration for Mechanical Systems

Effective Water Filtration

A great design is incomplete without proper water filtration. What’s effective water filtration for a mechanical system? It depends on who you ask. To demystify water filtration in mechanical systems, HIGHMARK created this guide to highlight the minimum filter requirements and recommend the most energy- and water-efficient solutions.

The Criticality of Water Filtration

The importance of filtration in air systems is easily understood. However, when it comes to water filtration, it tends to be a bit murky. To clear the water, particle contamination can cause inefficiencies in the system, not to mention fouling or bio-film build-up and acid erosion, which shortens the equipment’s lifetime. Cutting out adequate filtration to save money now can end up costing more in the future. And in open-loop systems, the costs to the community are far worse, with the potential of a Legionella outbreak due to inadequate filtration.

Local Law 77 Requirements

In August of 2015, NYC officials responded with Local Law 77. This was after several Legionella outbreaks and nearly half of the inspected cooling towers in the city testing positive for Legionella. This code requires all cooling towers, evaporation condensers and fluid coolers to be registered with the New York State and Department of Health and Mental Hygiene. Further, the systems must follow a maintenance program in compliance with ASHRAE Standard 188P.

Particle Size and Systems

Fine particles 1-5 microns are the first to cling to surfaces, which causes fouling. These finer particles then feed on larger particles, and the problem grows. To get a sense of particle sizes, an average human hair is 150 microns.

Knowing the particle size to be removed for a particular system is a crucial part of selecting filters that significantly improve the efficiency of the system. Open systems see larger particle sizes than closed-loop systems, which only see fine particles less than 10 microns. It’s essential to add a filter for large particle sizes greater than 10 microns in an open system. The chemical treatment will work with the filter to remove the finer particles.

Types of Water Filtration

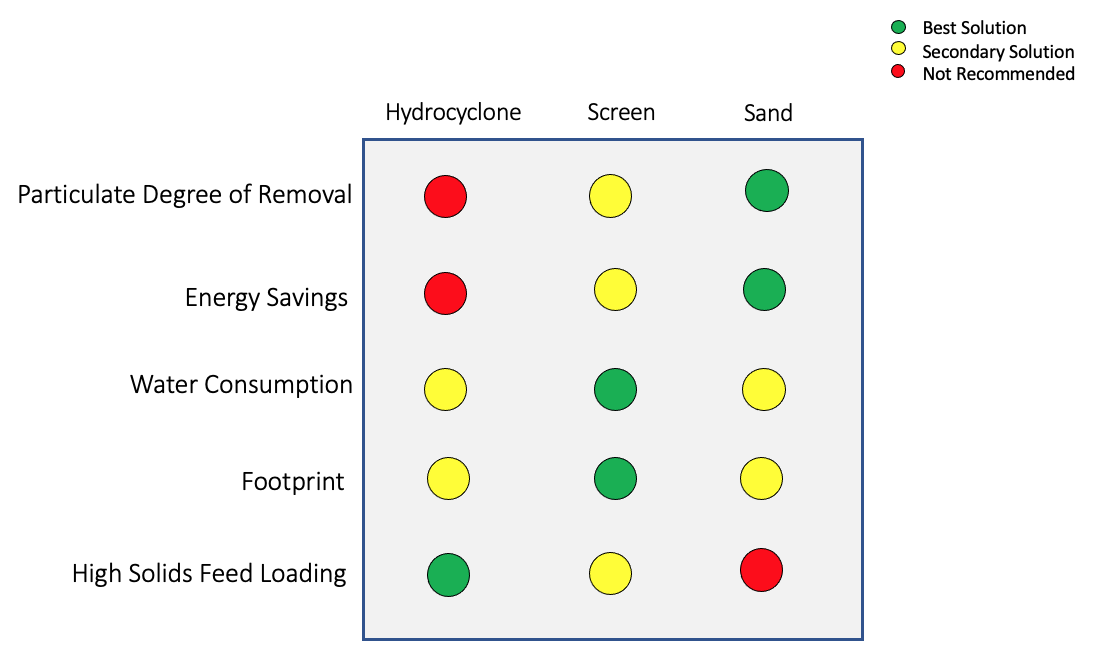

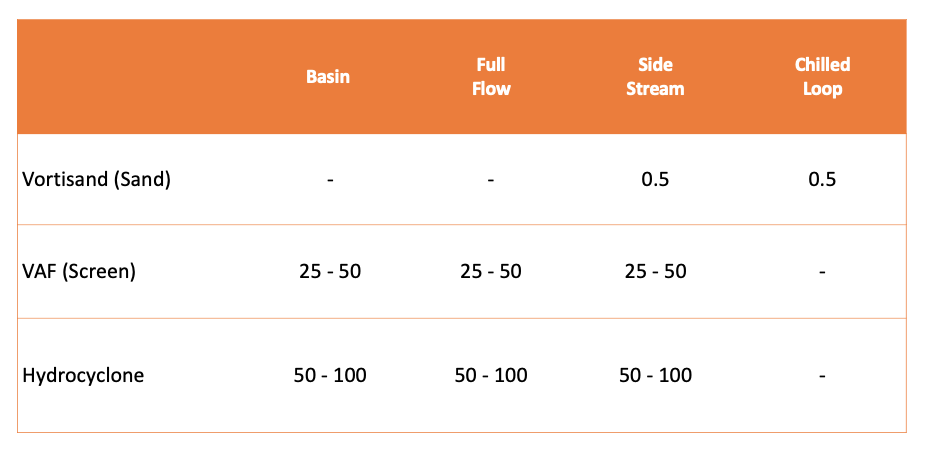

Types of filters that work well in this application are screen filters, sub-micron sand filters and hydrocyclone separators:

- Screen Filters

- Remove particles less than 10 microns

- Go long periods without maintenance

- Stay online while backwashing

- Sub-Micron Sand Filters

- Remove particles less than 1 micron

- Prevent tunneling by using tangential flow, unlike traditional sand filters

- Use less water for backwash

- Hydrocyclone Separators

- Low-cost option that removes particles greater than 100 microns

- Spin water in a tight column and use the resulting force to remove high-density solids in the water

- Use in series with screen and sand filters as a pre-filter to reduce the load on downstream filtration

Selecting the Optimal Water-Filtration System

Water-Filtration Strategy

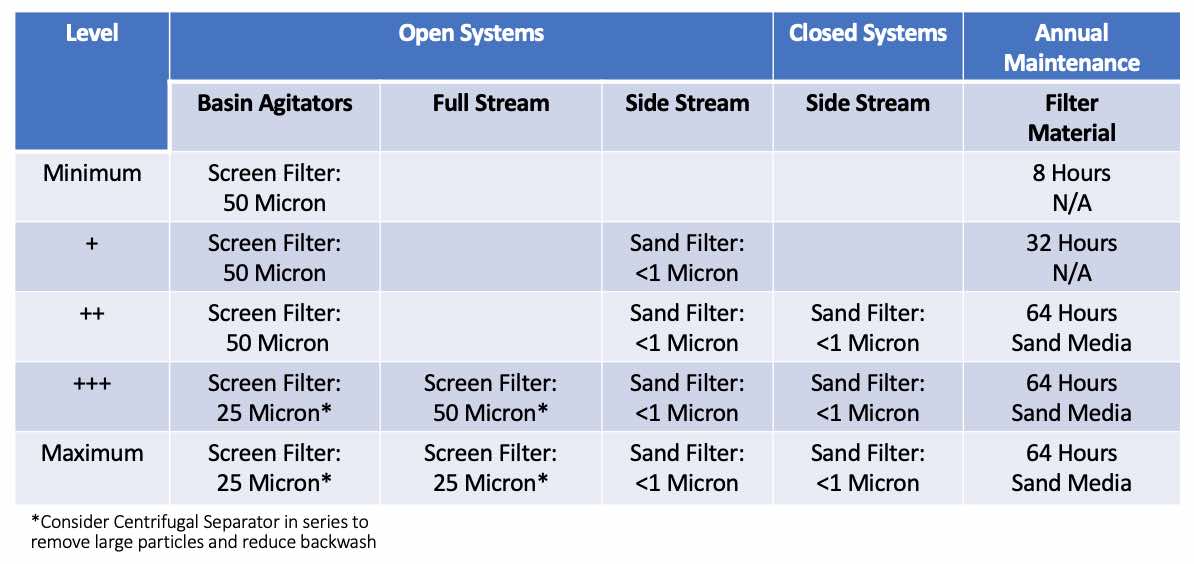

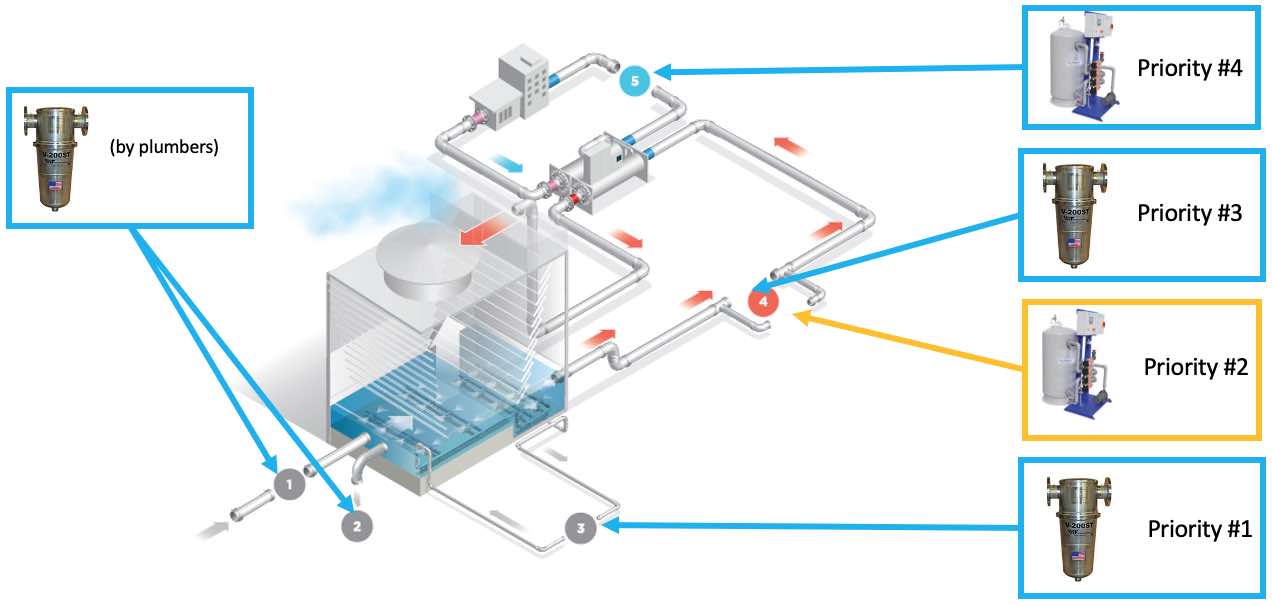

After selecting the filter type and particle size, the filter strategy is another crucial factor in water filtration for mechanical systems. One method to prevent growth in open systems is to keep the water moving with a basin agitator. This strategy keeps the solids suspended for ease of removal. Consequently, this reduces system maintenance and manual cleaning and enhances the chemical treatment’s performance.

For both open and closed-loop systems, the most effective way of removing contaminants is to run 100% of the system’s water through the filter. However, full stream filtration tends to be pricey. Another option to reduce costs is side-stream filtration, which deviates about 5-10% of the system’s water through a filter. The entire system will be filtered as much as one to three times per day or as little as one time every five days, depending on the design. In addition, considerations must be made for domestic water via auto-clean filters and potable water filtration.

- Priority 1: Separator in series with basin-agitator screen filter.

- Priority 2: Separator in series with either a side-stream sand filter or side-stream screen filter.

- Priority 3: Separator in series with a full-stream screen filter.

- Priority 4: Full- or side-stream sand filter for closed-loop system.

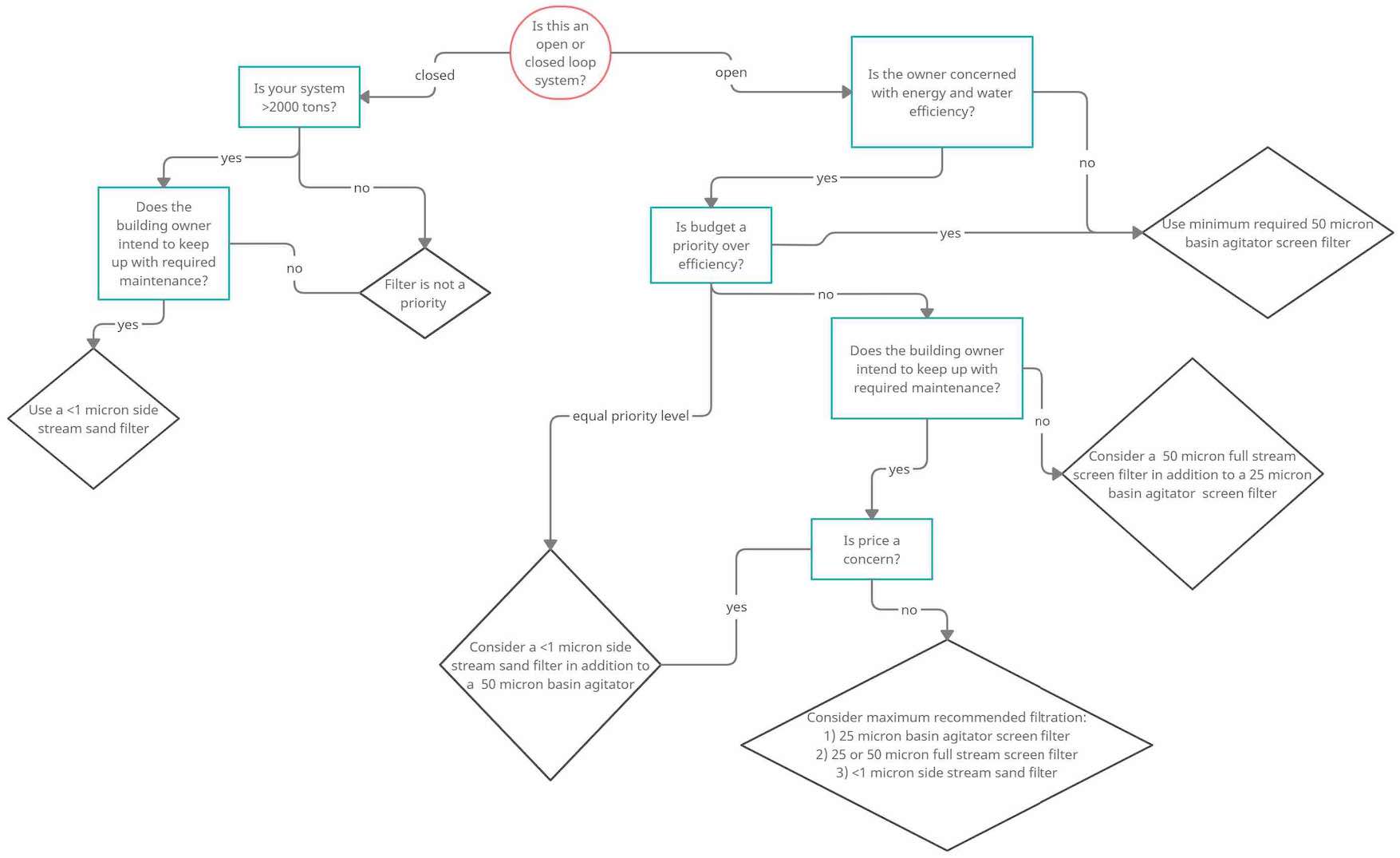

Water-Filtration System Decision Tree

Use this water-filtration decision tree to help you select the right system for your project.

In Summary

In conclusion, proper water filtration in mechanical systems is critical. It creates healthier communities, improves the system’s lifespan and efficiency and can save money in the long run. Along with this guide, you can view a full on-demand webinar on this topic. For information on specifications and selecting the best system, please get in touch with us via the contact form below.